Ultimate Carrier Gas Safety

Abstract

Ultimate hydrogen gas safety can achieved by a system that controls hydrogen supply and that burns all excess carrier gas and chemicals. This makes it finally possible to fully benefit from the use of Hydrogen in gas chromatography. This approach increases overall safety in the lab and creates a healthier laboratory environment. Adding a Hydrogen generator to supply gas on demand, no more cylinders, piping or regulators are needed, leading to a significant cost saving and a fast return on investment.

HIGHER THROUGHPUT, FAST ROI

Hydrogen:

Shorter analysis times and higher efficiency, but safety issues.

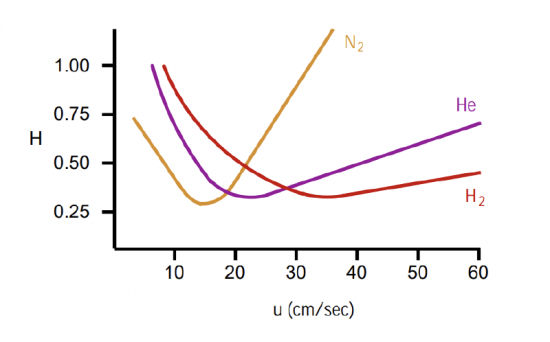

Many laboratories want to achieve the highest possible throughput of samples while achieving the best possible separation. Looking at the Van Deemter plot, we know that hydrogen is the best carrier gas for gas chromatography. With its optimum linear velocity of 40 cm/sec, hydrogen offers much faster analysis times, and can therefore considerably change the throughput of the lab. In addition, the cost of hydrogen is much lower than that of Helium. However, the use of hydrogen gas brings a lot of safety issues, so that many lab managers hesitate to use hydrogen.

HYDROGEN: BEST CHOICE AS LONG AS SAFETY CONTROLS ARE IN PLACE

The future: Smart control of hydrogen in the lab

• Cylinders, Piping, regulators require regular maintenance as well as downtime.

Using gas cylinders has many disadvantages and is costly because of installation cost and regular maintenance required for piping and regulators. Depending on the need of carrier gas, the cost can easily go up to $30.000 per year. There is also considerable downtime to exchange cylinders as well as time needed to equilibrate the system when changing empty gas cylinders. These gas installations are not only costly, but they also require much more safety measures in the laboratory.

• Hydrogen generator as a better alternative

Generators deliver hydrogen on demand and only store a minimum of hydrogen in the system. Therefore, they offer a much better alternative for carrier gas supply than using gas cylinders.

Using a proton exchange membrane, hydrogen can be made from distilled water by electrolysis. A generator able to supply high flow rates can simultaneously supply carrier gas to multiple gas chromatographs in the laboratory and can supply hydrogen fuel gas at different flow rates to FPD, PFPD, NPD and FID detectors. The generator will also shut down as soon as a leak is detected.

Although the use of the hydrogen generator is much safer than using gas installations with cylinders, there are still safety issues. Hydrogen carrier gas venting is still needed as well as solutions for a possible accumulation of high amounts of hydrogen. Venting from the split vent and septum purge is necessary to eliminate this risk. Excess chemicals, vented into the lab atmosphere can cause cancer and present a health issue that needs to be taken care of.

• UCS1000 Ultimate carrier gas safety system for maximum safety in the laboratory.

UCS1000 is based on a patented groundbreaking technology, which finally allows labs to leverage the power of Hydrogen safely and cost-effectively.

UCS Operation principle

As indicated in picture, the UCS1000 controller box continuously control Hydrogen supply to the GC. It has an automated protection against flame off, power loss, low gas supply pressure and more increasing overall safety of using hydrogen as a carrier gas. It will also eliminate Hydrogen build up in the GC/MS after a power recovery.

Both split vent as well as septum purge are directed to the burner unit of the UCS1000 so all excess carrier gas is burned and does not end up in the lab atmosphere.

Burner unit and controller unit are completely separated. The UCS1000 has also an internal alarm as well as external alarm contacts. In addition, a Multi Carrier gas option is provided to easily change carrier gas to Helium or Nitrogen directly from the control screen.

UCS1000 ultimate safety for H2

Changing to Hydrogen as a carrier gas with the benefit of shorter analysis times and higher sample throughput is now possible with much better control of overall laboratory safety. In addition, this solution offers a return on investment (ROI) within one year because of all the cost savings!